Thane, Maharashtra

- GST NO. : 27BSCPG1776J2ZK

+91-8928472954, +91-9773340777

Pharmaceutical Mill Machines

Leading Manufacturers, Exporters and Wholesaler of Comminuting Mill Machine, Cone Mill Machine, Stainless Steel Colloid Mill Machine and Stainless Steel Multi Mill Machine from Thane.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Finishing | Polished |

| Driven Type | Electric |

| Packaging Type | Silver |

| Condition | New |

| Pressure | Medium Pressure |

| Specialities | Easy To Operate |

| Total Carbohydrate | 2 Years |

| Country of Origin | India |

| Operating Mode | Automatic |

Comminuting mill is used for the downsizing, milling, pulverization and dispersion of wet and dry products in pharmaceutical, chemical, food, cosmetics, fertilizers industry etc.

The product is poured from the top through in feed hopper and material falls on the rotor blades beater assembly for milling or pulverization. Due to the knife edges mounted on rotor, the downsizing of particle takes place and through sieve material gets pushed outward from the bottom opening. Knife edges can be removed for cleaning very easily.

SALIENT FEATURES

· Design is cGMP – Current Good Manufacturing Practices compliance.

· All Product contact parts AISI 316/ 316L & non-contact parts AISI 304.

· Easy and simple to change knife to impact forward vice-versa by reversible chamber.

· Wide range of sieve of perforated and wire-mesh.

· Fitted on castor wheels for easy mobility.

OPTIONAL FEATURES

· Jacketing chamber for water cooling.

· AC frequency drive for variable speed,

· Explosion proof motor and push button,

· Fixed / swing type beater assembly

· Uniform feeding system with feeder screw with variable drive.

SAFETY FEATURES

· Interlocked throat hopper and belt guard & Over load relay protection.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Finishing | Polished |

| Driven Type | Electric |

| Color | Silver |

| Automation Grade | Automatic |

| Warranty | 1 Years |

| Country of Origin | India |

| Shape | Conical |

Boinns Cone Mill is a special machine you can use in the pharmaceutical, food processing, or any other industry for size reduction. It reduces the sizes of large products, which can be hard or medium into small, soft pieces.

Reducing the size of dry material in a product, this increases the surface area of material hence increasing its solubility rate

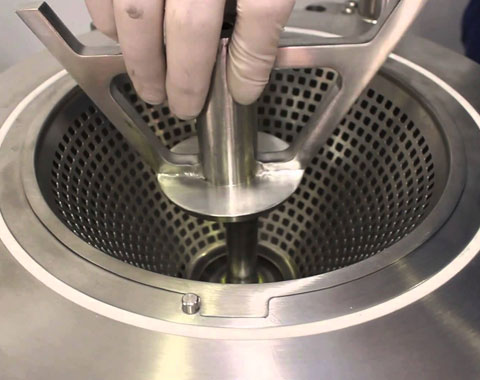

Unprocessed material is loaded into the product inlet of the Cone Mill by hand, gravity-feed or vacuum transfer. The material then passes into the milling chamber where a rotating impeller forces the unprocessed material through stationery cone-shaped screen by a vortex action.

The material is instantly reduced in size as it passes through the holes in the screen. By changing a combination of screen, impeller-shape and speed, the finished milled particle size can be carefully controlled.

Features

Compact size, Fast screen changes, Easy clean GMP design

SS 316 contact parts SS 304 Non-contact part

An extensive range of replacement screens are available.

Imported Laser Driller Mesh for Dry application

Safety Standards with no outside cables

Vacuum Loading option

Bin charging Loading system option

Dust free closed system for charging and discharging of powders or granules

Different profile of blade and sieve available

High speed shredding, sizing & grinding

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Finishing | Polished |

| Packaging Type | Silver |

| Condition | New |

| Pressure | Medium Pressure |

| Operating Type | Automatic |

| Usage | Industrial Use |

| Total Carbohydrate | 2 Year |

| Country of Origin | India |

Boinns colloidal mill is a machine that is used to reduce the particle size of a solid in suspension in a liquid, or to reduce the droplet size of a liquid suspended in another liquid. This is done by applying high levels of hydraulic shear to the process liquid. It is frequently used to increase the stability of suspensions and emulsions the colloid mill is used for various applications such as Superfine grinding, Homogenizing, emulsifying, dispersing, mixing and extracting of liquids, ointments and highly viscous

Products in pharmaceutical, cosmetics, suspensions & emulsion industry.

Process: The product is fed to the hopper which leads the product into the gap between rotor and stator. The Product is subjected to a high degree of shearing, cutting and rubbing between two metal toothed Surfaces of rotor and stator and towards the discharge section. The processed product continuously Leaves the mill through drain pipe if required, it can be re-circulated by three-way cock and recirculation

Pipe assembly

Design is cGMP – Current Good Manufacturing Practices compliance.

All contact parts AISI 316 & non-contact parts AISI 304.

Easy to adjustment gap between rotor and stator.

Three-way cock assembly with re-circulating pipe.

Easy to Moveable and dismantle all contact parts for cleaning.

Silicon food grade seal.

Water cooling system for housing, hopper & recirculation pipe.

Safety Features:

Overload pressure release mechanism.

Emergency stop button.

| Business Type | Manufacturer, Exporter, Supplier |

| Usage/Application | Industrial Use |

| Material | Stainless Steel |

| Color | Silver |

| Automation Grade | Automatic |

| Warranty | 2years |

| Finishing | Polished |

Boinns Multi mill is used for high-speed Granulating, Pulverizing, Mixing, Shredding and Chopping, etc. of a wide range of wet and dry materials without special attachments.

Multi mill operates on the principle of variable force swing beaters having both knife and impact edges rotating within a selected screen to get the required size reduction. Material fed in the hopper, goes down to the processing chamber where it moves to the periphery and passes through the screen radially and tangentially avoiding chocking and temperature rise. Finally, the processed material gets collected in the container kept below the processing chamber.

Output and quality of the final product depends on three main factors:

Shape of beaters (knife/impact edges)

Speed

Screen.

FEATURES

Machine Portable on Castor wheels, High output with Process uniformity, All contact parts are in SS 316, Built in Variable Frequency Drive for multiple speeds

Direction of the Blade rotation can be changed using a Reversing switch for Hammer or Knife operation

Multiple combinations of Screens / Speeds / Screens / Speeds / Amount of Blades / Direction of blade rotation for every Product type

Higher Screen opening area, Minimal material handling resulting in Total Dust free operation

Easy Dismantling and Cleaning of all Components reducing Production Downtime and increasing Productivity

Wide range of SS perforated and Wire knitted screen available for every Product type

Additional perforated screen at the bottom of pulverizing chamber ensuring Higher Fineness and Controlled Size of Granules